| Business Type | Manufacturer, Exporter, Supplier |

| Preferred Buyer From | Global |

With the rapid advancement in manufacturing technology, consumerism has increased over the years. Therefore, to meet the higher demands, manufacturers have come up with innovative methods of producing high-quality products at a much faster rate.

The production process has observed the introduction of inventive manufacturing concepts such as Lean Production System, Cellular Manufacturing, Single Minute Exchange of Dies, and Tact Time Analysis. These creative approaches require the need for a horde of efficient, cheaper tools, and work-holding devices.

The manufacturing company requires a simple work positioning strategy and devices for correct operations. This is to ensure:

- Non-complexities in assembly and unit cost reduction,

- Reduction in the massive manufacturing cost, and

- Increase their profitability.

The industry has resorted to easing upthe supply chain in a bid to maintaining a low amount of inventory. This resulted in the emergence of better and cost-effective work-holding devices which ensure better quality products, increase throughput, and reduce lead time. The requirement for production standard work-holding devices has paved the way for two specific terms named: Jigs and Fixtures.

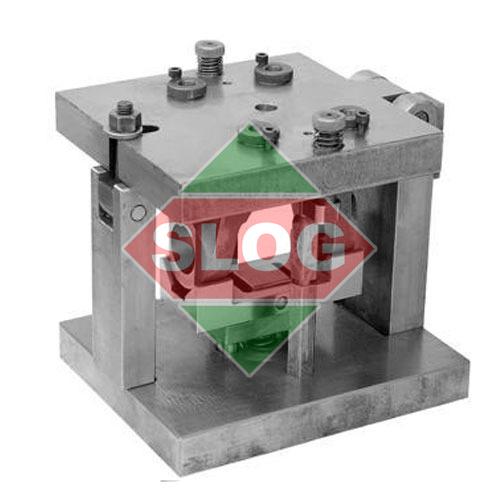

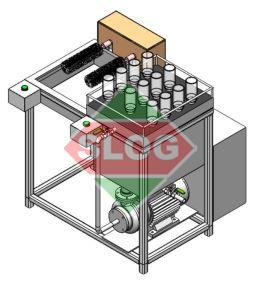

The jig is the device which guides the tool, while the fixture is a tool that securely and firmly holds the job in position during machining operations.

Details

| Jig | Fixture |

| A jig controls and guides the machining tool | A fixture holds and supports the component precisely for machining operations |

| Jig ensures accuracy, repeatability, and interchangeability | The fixture provides a reduction in error by holding a component firmly on a table |

| Jigs are usually on the lighter side | The fixture is bulky, rigid and heavy |

| Jigs can be put in place and held by hand pressure | Fixtures are always placed firmly on a machine table |

| Drilling, reaming, tapping, boring are some of the standard jig functions | Fixtures are used explicitly in milling machine, slotting machine and shapers |

| Jigs cost more | Fixtures are not that cost-savvy compared to Jigs |

| Jigs require intricate design operations | Fixture design operations are relatively less complicated |

Looking for "Jigs and Fixtures" ?

Explore More Products